Bicycle maintenance guide: Chains, wear and replacement

Bicycle maintenance guide: Chains, wear and replacement

Posted on 8 Nov 2017

When it comes to the most important parts of a bike, the chain is certainly up there in terms of the most essential. Without it there's no connection between your human input and the mechanical output of the bike-in simple terms you're going nowhere fast!

However, like the majority of bike parts, it is not immune to wear so regular maintenance is required to get the most out of your chain. Even with regular maintenance though there will come a time where it is too worn to continue being used on the bike and will need replacing.

Continuing to ride a bike with a worn chain is a sure-fire way of running up a nasty repair bill when you take your bike to your local workshop, so Graeme from Torq Zone Academy is here to share some of his knowledge about chains, how to know if they're worn and what to look for when replacing them.

The anatomy of a chain

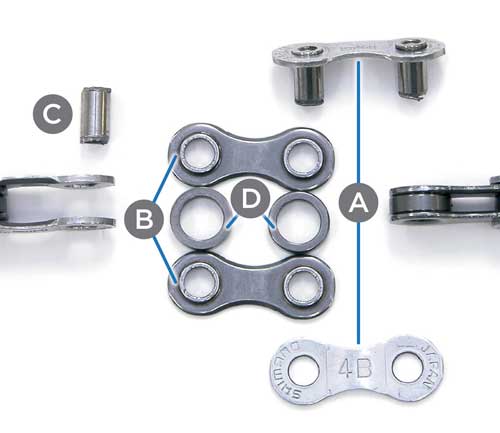

Chains are made up of multiple pairs of outer and inner plates held together with rivets. Rollers space each pair of inner plates with rivets being pressed into place through both outer plates to hold the assembly in place, with the inner plates and rollers pivoting freely on the rivets.

Each ‘set' forms one link (i.e. one of each of the outer and inner plates), which are 1 inch (25.4mm) in length. Chainrings and sprockets are therefore designed to accommodate this length between the teeth.

Chain width is measured over the rivet length. With the introduction of more sprockets on the cassette, spacing becomes more and more limited and chain, therefore, become narrower and narrower. With width of the chain having a direct relation to the number of sprockets, chains are therefore sized according to their "speed". For example an 11 sprocket cassette requires an 11 speed chain, a 10 sprocket cassette requires a 10 speed chain and so on. Failing to fit the correct speed chain could result in inaccurate shifting or the chain jamming between the sprockets.

Chain wear

On the inside of the inner plates are bushings which hold the rollers in place and which the rivet is pressed through. At this interface two types of wear take place, namely rivet-on-bushing wear and bushing-on-roller wear. Rivet-on-bushing wear is the primary cause of chain elongation.

NB: You may sometimes hear people saying that a chain will ‘stretch' over time, however this isn't technically true. It may appear so, but as mentioned above what is actually happening is the moving parts of the chain are slowly wearing away. Multiply this wear by the number of links in a chain, and the overall wear adds up to ‘elongate' the length of the chain.

Further, chain lubricant attracts dirt and grime which then forms a grinding paste and leads to additional wear at the rivet-on-bushing and bushing-on-roller interfaces. Cleaning the chain properly therefore prolongs the life of the chain.

Excessive chain elongation can lead to the rollers not seating within the chainring and sprockets correctly, which will in turn lead to premature wear on these components if not replaced. Having to replace your chain, cassette and chainring all in one go isn't going to be kind on your wallet!

Always clean the chainrings and sprockets with a brush before cleaning the chain. Use a recommended solvent and always follow up with warm, soapy water. A good chain cleaning tool is handy when cleaning the chain while on the bicycle. Always allow the chain to dry before re-applying lubricant.

Checking your chain

Chains should be regularly checked for elongation using a chain checking tool. Generally chain checkers indicate either 0.5% or 0.75% percentage of wear. As a general rule of thumb, 9 speed chains and below should be replaced at 0.75% elongation, and 10 speed and above chains replaced at 0.5% elongation.

Sizing a new chain

The easiest way (and just as accurate a method) to size a new chain is to run the chain around the largest sprocket at the back and largest chainring on the front, bypassing the front and rear derailleurs. Make sure the chain seats correctly between the chainring and sprocket teeth, and that at the ends you have an inner and outer plate coming together on the chainring (you may need to add a little slack on the chain to ensure this).

If using a connecting rivet then add one link on a hardtail bicycle and break the chain at this point. On a dual suspension bicycle add two links and break the chain at this point.

If using a master link add half a link on a hardtail bicycle and break the chain at this point. On a dual suspension bicycle add one and a half links and break the chain at this point.

When fitting the chain to the bicycle ensure that it runs correctly through the front and rear derailleurs before inserting the connecting rivet or master link. Some chains and master links are directional so check the manufacturer's specifications. One more thing to note with connecting rivets is that they should be pressed in from the inside of the chain.

Manufacturers design their chains to work as part of the wider system (i.e. with the front and rear derailleurs, cassette sprockets, chainrings, and gear levers). Chains can vary in outer plate design and sizing, where differences can cause inaccurate shifting between brands and models. Chains will also vary in the quality of material used with better quality chains being more durable.

When in doubt about chain selection it's usually best to stick to the component manufacturer's own chains as it does get more complex when components become mixed. Don't forget though that you can also seek advice and recommendations from your nearest Cytech qualified technician!